I was back in Scotland just before Easter weekend. On Easter Sunday, mum and I drove west from Glasgow. We stopped at Loch Fyne Oysters where we had breakfast and bought some fresh fish and meat and then Fyne Ales where we bought a 5l mini-cask of they’re very ‘fyne’ Jarl light ale. We had lunch at the Kitchen Garden in Oban before getting the ferry over to Mull and another from Tobermory to Kilchoan on the Ardnamurchan peninsula. The ‘CalMac’ ferry ‘Hopscotch’ saved a much longer drive and the new government subsidised pricing makes attractive as well as scenic and relaxing. From Kilchoan it was a short drive to the lighthouse.

I had booked one of the lighthouse keepers cottages for a few days. [image: Inline images 1] The pink granite blocks from nearby Mull are massive and none of these buildings are likely to change within another several hundred years.

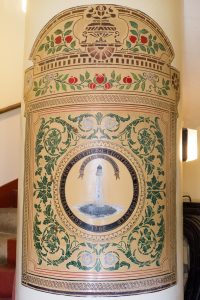

[image: Inline images 2] A beautiful painting on the central pillar at ground level in the doorway. I am quite sure this was painted around 1849 when the lighthouse was built.

Author Archive

Ardnamurchan

Monday, May 8th, 2017The new home is blog.erikbloodaxe.nz

Tuesday, January 17th, 2017Yes, I’ve been bludging my wee bro’s web service provider for years for my blog. A few years ago it suggested I upgrade WordPress, but failed with an error. Every year or so it gets more insistent, but still fails to update. I’ve finally got around to subscribing to my own hosted web server. Took a couple of days to get the ‘erikbloodaxe.nz’ domain registered and another couple of evenings to get the sub-domain setup right and copy across the old blog contents. I’ll endeavour to keep it updated more frequently. One plugin I tried to setup on the old blog site was the ability to email new posts to the blog server, but it never worked. The new blog version will hopefully fix that.

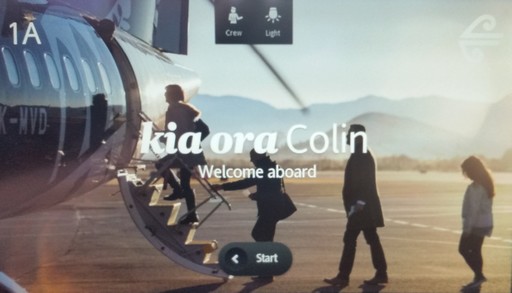

Dreamliner

Saturday, October 24th, 2015Just over a week ago I had my first flight on one of Air New Zealand’s new Boeing 787-9 Dreamliner’s. I had been at a conference in Sydney and flew out back to Auckland mid morning on the Friday. On some flights on this sector AirNZ use long-haul Aircraft, so 777-200/300, or Dreamliner, even though it is a short-haul flight. Just so happened I was on a Dreamliner. On these trans-Tasman and Pacific Islands short-haul routes Air NZ have basic ‘Seat’ and ‘Seat + Bag’ non-changeable options and ‘The Works’ and ‘Works Deluxe’ which are changeable and include food and entertainment in the price. The latter two options put you towards the front of the plane and ‘Deluxe’ guarantees an empty seat next to you on the single aisle Airbus A320. On the Dreamliner, ‘The Works’ puts you at the front of Economy, or in Premium Economy, and ‘Deluxe’ puts you in Business Premiere. I was on a ‘The Works’ ticket, changeable in case of a change of plans which has happened a few times, but I had an Elite short-haul recognition upgrade which bumped me into business. I normally fly long-haul from NZ, so it was nice to be able use a short-haul upgrade for a change. As a frequent flier, you can select your seats online in advance rather than just within the 24 hour online check-in period. So, my first flight on a Dreamliner was in seat ‘1A’.

The Business Premiere seats were developed for the 777-300 and then also used in the 747, now out of service with Air NZ, and 777-200 when they were overhauled, and now the Dreamliner. They don’t fit the Dreamliner as well as the other aircraft as it is seemingly a narrower body. Very comfortable nonetheless. Despite being called ‘Works Deluxe’, it is in fact the full Business Premiere service from long-haul. You get linen, crockery, metal cutlery, attentive service and food developed by Peter Gordon and his team – he has 2 or 3 restaurants in both Auckland and London. So, a 3 hour flight was more like a long lunch in a good restaurant, with fabulous food and excellent NZ wines. So, if you’re planning a trans-Tasman or Pacific Island flight with Air New Zealand, I recommend you check out which aircraft are available and book accordingly for a very pleasant experience over the regular bus trip in an appropriately named short-haul Airbus.

Christmas Present 2014

Wednesday, April 15th, 2015My present to myself this last Christmas was a PowerCRAFT TIG 200 AC/DC welder. It’s made by Lincoln Electric, one of the big US welder manufacturers. They are clearly competing against the widely available cheap Chinese welders and, whilst it is using their technology, it is manufactured in China. It can weld steel and stainless steel, as well as aluminium, magnesium, titanium and zinc, probably more.

Bike-lift cum work bench/welding table.

Monday, January 26th, 2015Wow, over 2 years since my last post. Every so often, probably every few months, work becomes busier than ever, but it never gets less busy, so that’s the new norm until it gets busier again…

Anyway, my knees are not so good after years of crawling around on rocks manhandling seals when we were tagging them. I always take kneepads on the rare occasions I get into the field now. That also means I’m done with crawling around on my knees servicing my motorbikes, so I built a multipurpose bike-lift/workbench from scratch using a cheap trolley jack to lift it. The bench sits at 250mm when lowered and there is a ramp which clips on to run the bike up and down. For bike work it will only be lifted to 400mm, or 500mm, but the bench can be lifted to 900mm and locked at every 100mm increment in between. At 800mm, or 900mm it is a heavy duty bench for engine/gearbox work and a welding bench – earth the bench and for most welding jobs, contact is made through the bench.

It’s been built over a few months inbetween travel, but I’ve finished it during the Xmas/New Year break. I used my landlord’s industrial MIG welder for a lot of the structural stuff, not to mention his vertical milling machine for the precision drilling, as well as his metal bandsaw and guillotine. My Xmas treat to myself was a 200Amp AC/DC TIG welder which has been used to finish the job.

The picture shows the Speed Triple on the lift for a quick service, the ramp only fits when the table is fully lowered.

Auckland Island Pigs

Thursday, June 21st, 2007

We sailed from Bluff on the Clan McLeod …

… a thirty hour passage. We arrived just after dark with no idea if the helicopter had managed to fly down that day or not.

As it happened the helicopter had arrived, so it lifted our gear and the drums of helicopter fuel to our land base on Enderby Island.

Our accommodation was the sea lion research station, normally only used between November and February – very comfortable.

There were possibly as many as a hundred southern right whales breeding in Port Ross, the sheltered inlet at the Northeast corner of the archipelago.

Lots of shy mollymauks flying around. Big birds! Very majestic.

One of the largest breeding colonies of yellow-eyed penguins is on Enderby Island with no cats or pigs to bother them. Here’s a picture of a penguin flying – sort of.

More to come…

ErikBlood@xe new blog

Wednesday, June 20th, 2007Blogging newbie. This continues where www.erikbloodaxe.net left off.